Manufacturing of mill balls

MANUFACTURING OF MILL BALLS Mill balls. Bodies for crushing of mineral ore are of various forms, such as a ball, cylinder, cylindrical pebbles and etc., and are made by means of

احصل على السعر

What is Ball Milling Process Dry Ball Milling ball mills

This article takes dry ball milling as an example to introduce the ball milling process. First, select the appropriate size and weight of the grinding medium according to the particle size of the

احصل على السعر

manufacturing process of ball mill balls

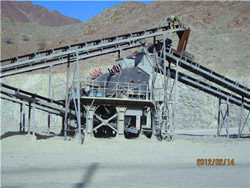

2021-6-6 Ball Mill Used For Sand Manufacturing Process 2020212 · Ball Mill Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture

احصل على السعر

The Manufacturing process for balls, stainless

2018-3-1 P.O. Box 330100 Railroad Place West Hartford, Connecticut 06133-0100 USA

احصل على السعر

Grinding balls manufacturing process -Melting, Molding

2022-7-5 Manufacturing grinding balls, there are four essential steps. First melting, second molding, third separating, and the last heat treatment. Melting. The furnace the factories most

احصل على السعر

The Precision Ball Manufacturing Process

2020-10-29 Steps in the Precision Ball Manufacturing Process. Raw materials are inspected. Cold heading machine cuts off proper length of the wire material, then forms the cylindrical

احصل على السعر

Manufacturing process of grinding media balls

2022-6-16 The process involves the following stages: 1. Incoming inspection of preform. For the production of grinding balls, Energosteel uses hot rolled round bar from medium and high carbon and low-alloyed steel produced by the

احصل على السعر

Ball mills Making

A ball mill uses the impact of metal or ceramic balls, falling from near the top of a horizontal shell to crush the material into fine particles. The outer cylindrical shell rotates to lift the grinding

احصل على السعر

Manufacture process of rolling ball, forging ball

2022-6-15 The production process of casting grinding balls: The casting grinding ball is a kind of grinding balls which uses the medium frequency electric furnace to melt the scrap steel, scrap iron and so on. The furnace charge is fully

احصل على السعر

Steel Ball Manufacturing Process Analysis

2019-9-19 Steel balls have become the necessary products for the crushing and grinding of mines in the world. There are three kinds of steel ball manufacturing process: forging, rolling and casting. Casting: The quality of cast steel balls

احصل على السعر

Manufacturing process of ball mill balls Manufacturer Of

Difference Between Sag Mill vs Ball Mill mech4st. Oct 12, 2017 The ball charge of a SAG mill is about 29% to 30% By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness The internal machinery of ball mill grinds the raw material into the powderlike material, And if extreme fineness and refinery are required then rotation go on

احصل على السعر

manufacturing process of ball mill balls Antek

Dec 15, 2020· Manufacturing. Method of balls rolling on ball- rolling mills is one of the most modern production methods.Transversal rollingof balls from the round billet is economical. It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase

احصل على السعر

procedures for manufacturing of ball mill

Ball mill manufacturing procedures.ball mill manufacturing procedur ball mill operating principles, components, uses, advantages and jan 11, 2016,ball mill is a milling machine that consists of a hallow cylinder,the maximum capacity ball mills are used for milling ores prior to manufacture of,methods of size reduction and factors affecting.Ball

احصل على السعر

manufacturing process of ball mill balls

2021-1-17 The Manufacturing process for balls Abbott Ball Company Every ball passes through exacting inspections that automatically detect and remove off-spec balls. A significant number of random samples is tested for hardness and examined microscopically for structure and finish.

احصل على السعر

Ball Mills Mineral Processing & Metallurgy

2017-2-13 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of

احصل على السعر

The Precision Ball Manufacturing Process

2020-10-29 Steps in the Precision Ball Manufacturing Process. Raw materials are inspected. Cold heading machine cuts off proper length of the wire material, then forms the cylindrical shape into a roughly spherical shape. Flashing removes any excess material on the perimeter of the balls. Heat treatment quench and temper process to decrease internal

احصل على السعر

Manufacturing Process Of Ball Mill Balls In South Africa

Ball Mill. Ball mill is the key machine to grind the crushed materials. Ball mill machine is widely used to process cement, silicate product, building material, refractory material, fertilizer, ceramics and glass, etc. Raymond Mill. On the basis of domestic mills, fote raymond mill is produced.

احصل على السعر

(PDF) Grinding in Ball Mills: Modeling and

2012-6-1 Rotary speed was set to 60 rpm in order to induce a cataracting regime for the balls [17, 27]. The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an

احصل على السعر

Ball Mill Grinding Media Steel Balls for Ball Mills AGICO

Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements. In a cement ball mill, generally, φ50-100mm steel balls are used in the coarse grinding chamber, φ20-50mm steel balls are used in the fine grinding chamber. 2. Short Cylinders

احصل على السعر

mill balls procedures at ironbridge cartecprzeglady.pl

ball mill manufacturing procedures vrolijk ts nl ball mills for alum manufacturing process In Malawi In Malawi Ball mill the free encyclopedia A ball mill is a type of grinder used to grind materials Locked charge starts and your grinding mill Outotec operating procedures ball mill operating loads mill balls procedures at

احصل على السعر

manufacturing process of ball mill balls

During the ball milling process, there are two factors that contribute to the exfoliation. The main factor contributing is the shear force applied by the balls. Using only shear force, one can produce large graphene flakes. Read More Ball Mill Working Principle And Main Parts. 2015-7-14 Ball Mill Working Principle.

احصل على السعر

manufacturing process of ball mill balls

2021-6-6 Ball Mill Used For Sand Manufacturing Process 2020212 · Ball Mill Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds

احصل على السعر

procedures for manufacturing of ball mill

Ball mill manufacturing procedures.ball mill manufacturing procedur ball mill operating principles, components, uses, advantages and jan 11, 2016,ball mill is a milling machine that consists of a hallow cylinder,the maximum capacity ball mills are used for milling ores prior to manufacture of,methods of size reduction and factors affecting.Ball

احصل على السعر

manufacturing process of ball mill balls

2021-1-17 The Manufacturing process for balls Abbott Ball Company Every ball passes through exacting inspections that automatically detect and remove off-spec balls. A significant number of random samples is tested for hardness and examined microscopically for structure and finish.

احصل على السعر

manufacturing process of ball mill balls

Feb 13, 2017 Ball Mill Manufacturing. Ball Mills for laboratories and pilot plants. Ball Mill Shell Dimensions VS Motor Sizes. In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill & ball mills, the ore in order to liberate the minerals.

احصل على السعر

manufacturing process of ball mill balls

Grinding balls manufacturing process -Melting, 2021-5-19 · The grinding ball is a grinding medium used in ball mill and material used in grinding mills, widely used in metallurgical mines, cement building materials, thermal power generation, flue gas desulfurization, magnetic materials, chemical industry, coal water slurry, pellet, slag, ultrafine powder, fly ash, calcium carbonate,

احصل على السعر

Manufacturing Process Of Ball Mill Balls

Ball Mill Machine In Manufacturing Process. Balls For Vertical Ball Race Mill Manufacturing Process . Ball mill wikipedia.A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringit works on the principle of impact and attrition size

احصل على السعر

The Precision Ball Manufacturing Process

2020-10-29 Steps in the Precision Ball Manufacturing Process. Raw materials are inspected. Cold heading machine cuts off proper length of the wire material, then forms the cylindrical shape into a roughly spherical shape. Flashing removes any excess material on the perimeter of the balls. Heat treatment quench and temper process to decrease internal

احصل على السعر

Ball Mill an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball

احصل على السعر

(PDF) Grinding in Ball Mills: Modeling and

2012-6-1 Rotary speed was set to 60 rpm in order to induce a cataracting regime for the balls [17, 27]. The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an

احصل على السعر